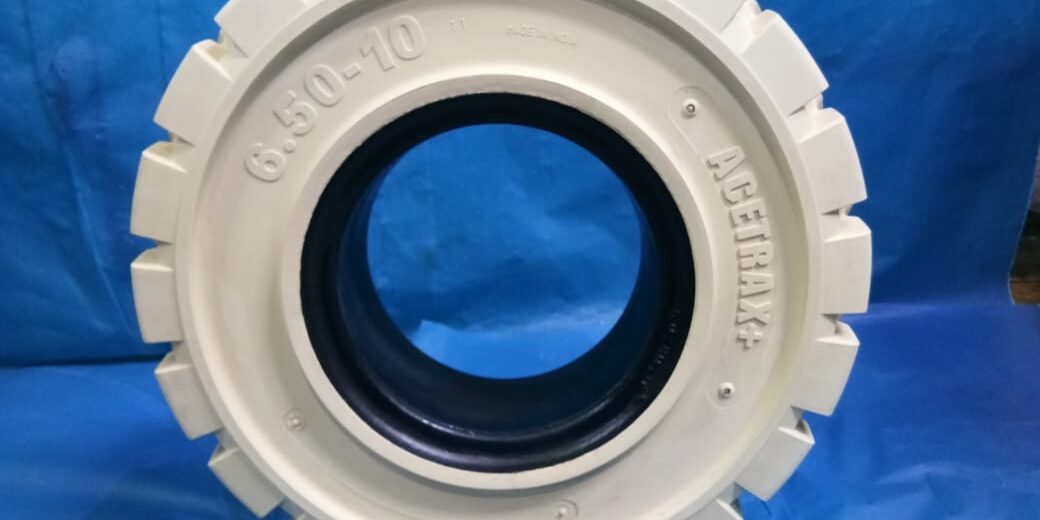

Non-marking tires are specialized white tires for forklifts that are designed to prevent dirt, residue, and marks from appearing on warehouse floors. They are available in cushion and solid pneumatic variants and have a softer compound, providing better flotation and a smooth glide across the ground. These tires are commonly used in retail stores, airports, food processing plants, and medical facilities to maintain a clean and visually appealing environment.

Pros

Eliminates floor marks, avoiding unsightly black marks on light-colored coatings and finishes.

Reduces cleaning requirements for industrial floors.

Offers performance similar to standard black forklift tires, with excellent traction, low rolling resistance, little heat build-up, high load-carrying capacities, and good tread life.

Suitable for use in medical/clean rooms due to their hygienic properties.

Provides UV protection comparable to standard tires, thanks to infused anti-oxidants during manufacturing.

Retains the core and base characteristics of reliable cushion tires.

Cons

Higher cost compared to standard forklift tires.

Wears out twice as quickly due to the softer compound, leading to increased replacement cycles.

Shorter life expectancy compared to black tires.

Lacks anti-static properties, requiring additional safety measures like equipping the equipment with earthing straps when working in flammable or explosive environments.

In conclusion:

The manufacturing process of non-marking tires replaces the soot commonly found in tires with silica, eliminating the black residue and ensuring they don’t leave marks on the floor.